The Mahindra Marksman:

The Mahindra Marksman:

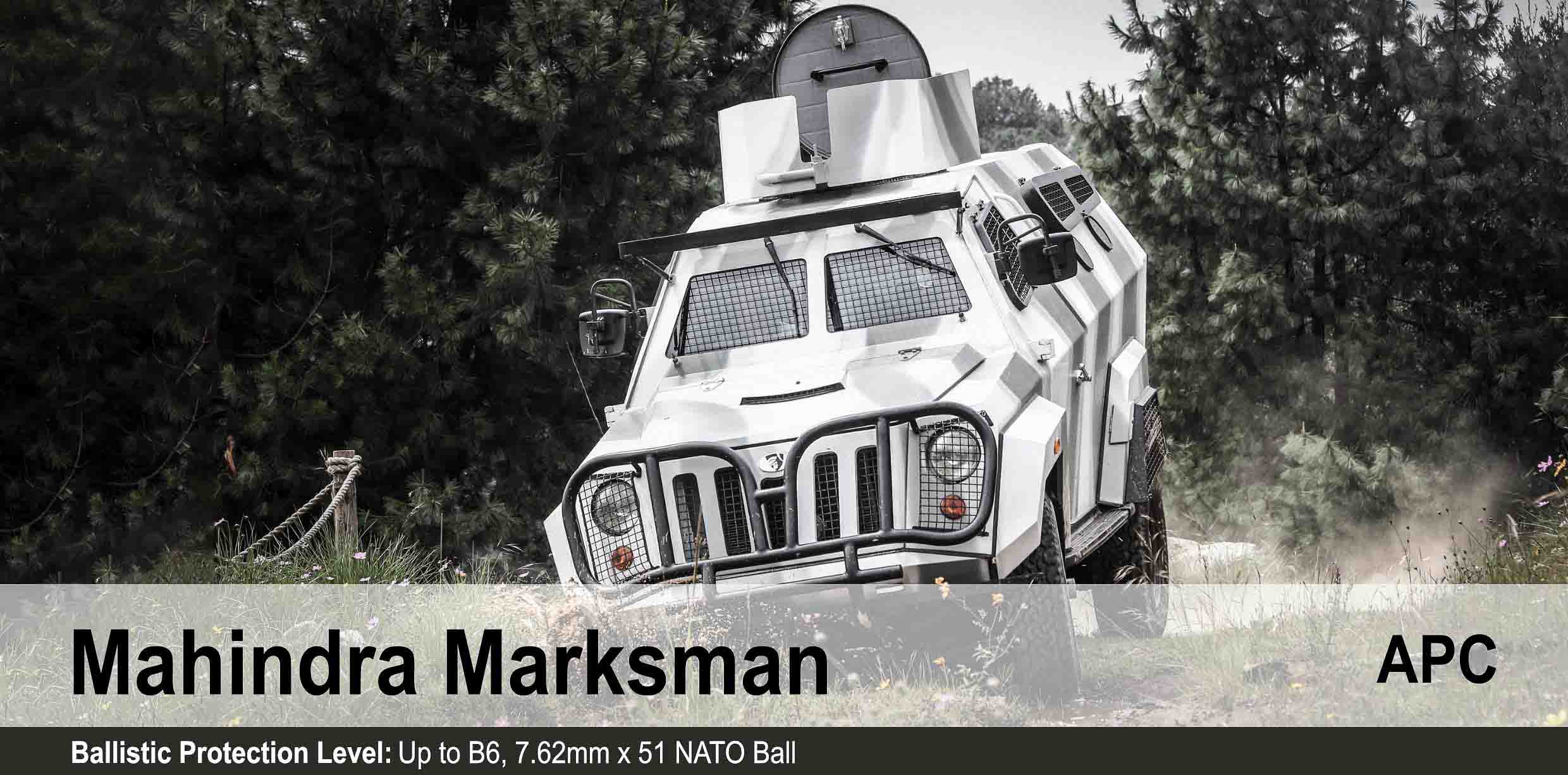

The Mahindra Markshman APC is a 4 + 2 seat Armoured Personnel Carrier (APC) offering protection against small arms fire and under belly grenade attacks.

Ideal for Border Protection and Riot Control.

Marksman is designed as a armoured capsule-based light bulletproof vehicle, it provides protection to the personnel of defence, paramilitary and police forces against small arms fire and grenade attacts. Armoured to Level B6, the

Mahindra Marksman has a Cuppola machine gun mount with 270* traverse and protection.

Five side armouring of passenger compartment (roof and

verticals) to provide protection against 5.56x45mm SS109 ammunition.

Floor blast protection against detonation of two DM-51 German

ordnance hand grenades or equivalent.

Ballistic steel interior frame provides overlap and backup

protection for impact areas, such as doors and windows.

Rear area protected by armoured swing door featuring view

glass and gunport.

Heavy duty door hinges installed to compensate the additional

armoured weight of all doors.

Marksman Specifications:

| Engine | Engine Type (option) | 2.2 Litre, m-hawk CRDe, turbo charged intercooled DI | 2.6 Litre, turbo charged intercooled DI |

| Cubic Capacity (cc) | 2179cc | 2609cc | |

| Power | 120bhp @ 4000rpm | 115bhp @ 3800rpm | |

| Torque | 280 Nm @ 1800 - 2800rpm | 228 Nm @ 1800 - 2200rpm | |

| Transmission | Transmission Type | 5 Speed Manual (5 Forward, 1 Reverse) | |

| Suspension | Front (option) | Independent Coil Spring, Anti Roll Bar, Telescopic Shock Absorbers | Independent Torsion Bar, Anti Roll Bar, Telescopic Shock Absorbers |

| Rear | Multi Link, Coil Spring, Anti Roll Bar, Telescopic Shock Absorbers | ||

| Brakes | Front | Caliper, Ceramic Pads and Ventilated Discs | |

| Rear | Drum and Brake Shoe System | ||

| Steering | Steering Type | Rack and Pinion Power Steering | |

| Turning Circle Radius | 5,600 mm | ||

| Drivetrain | Drive System (option) | 4WD | 4WD |

| Fuel | Type | Diesel | |

| Tyres | Tyre | Specifications LT 245 / 75R16 | |

| Seating | Vehicle Capacity | 6 (2 Front, 4 Rear) | |

Product Types

Do You Know?

Founded in 1945 as a steel trading company, Mahindra & Mahindra entered automotive manufacturing in 1947 to bring the iconic Willys Jeep onto Indian roads. Over the years, M&M diversified into many new businesses in order to better meet the needs of our customers. M&M follow a unique business model of creating empowered companies that enjoy the best of entrepreneurial independence and Group-wide synergies. This principle has led the growth into a US $19 billion multinational group with more than 200,000 employees in over 100 countries across the globe.